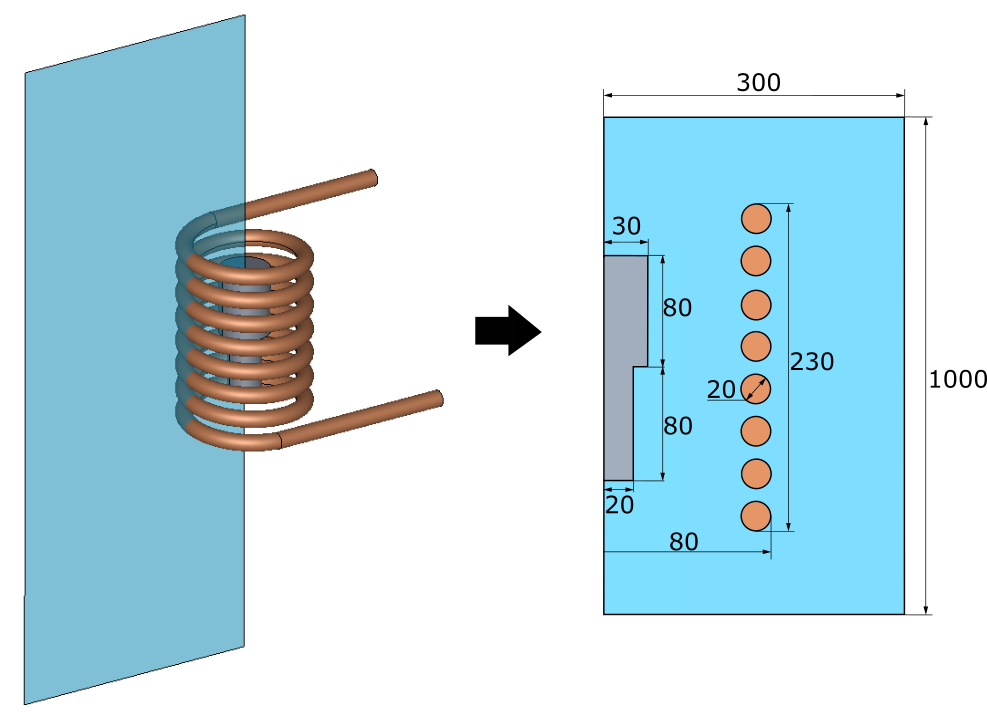

2D Stepped Workpiece Simulation

In this tutorial, you will become familiar with the steps needed to perform the preparation, setup and post-processing for 2D axial symmetric induction heating simulation of stepped workpiece. We will create geometry and mesh using CENOS pre-processing tool, then enter specific values and boundary conditions in physics part and in the end evaluate the results using our post-processor.

2D simulation is an easy way to predict thermal and electromagnetic fields within the object of induction heating. In this tutorial an induction heating example of an AISI 1020 workpiece at 10 kHz and 4 kA with radiation and convection boundary conditions is presented.

Download the application files:

2D Stepped Workpiece Simulation.pdf

Simulation_tutorial_2D_stepped_workpiece.zip

IMPORTANT: If you feel like you want to create this geometry using the old GEOM module, click here to open this tutorial for GEOM module.

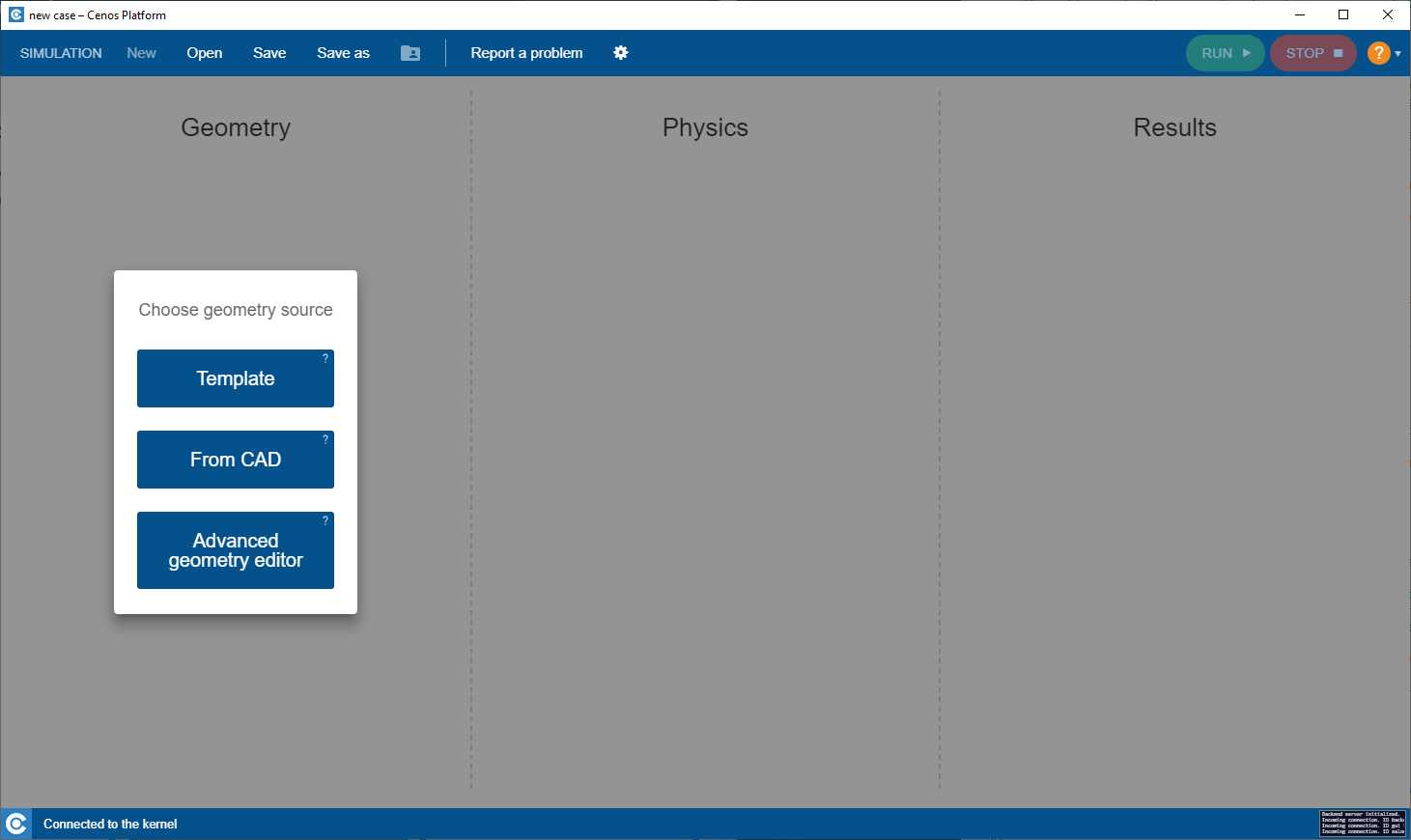

1. Open pre-processor

To manually create geometry and mesh, in CENOS home window click Advanced geometry editor.

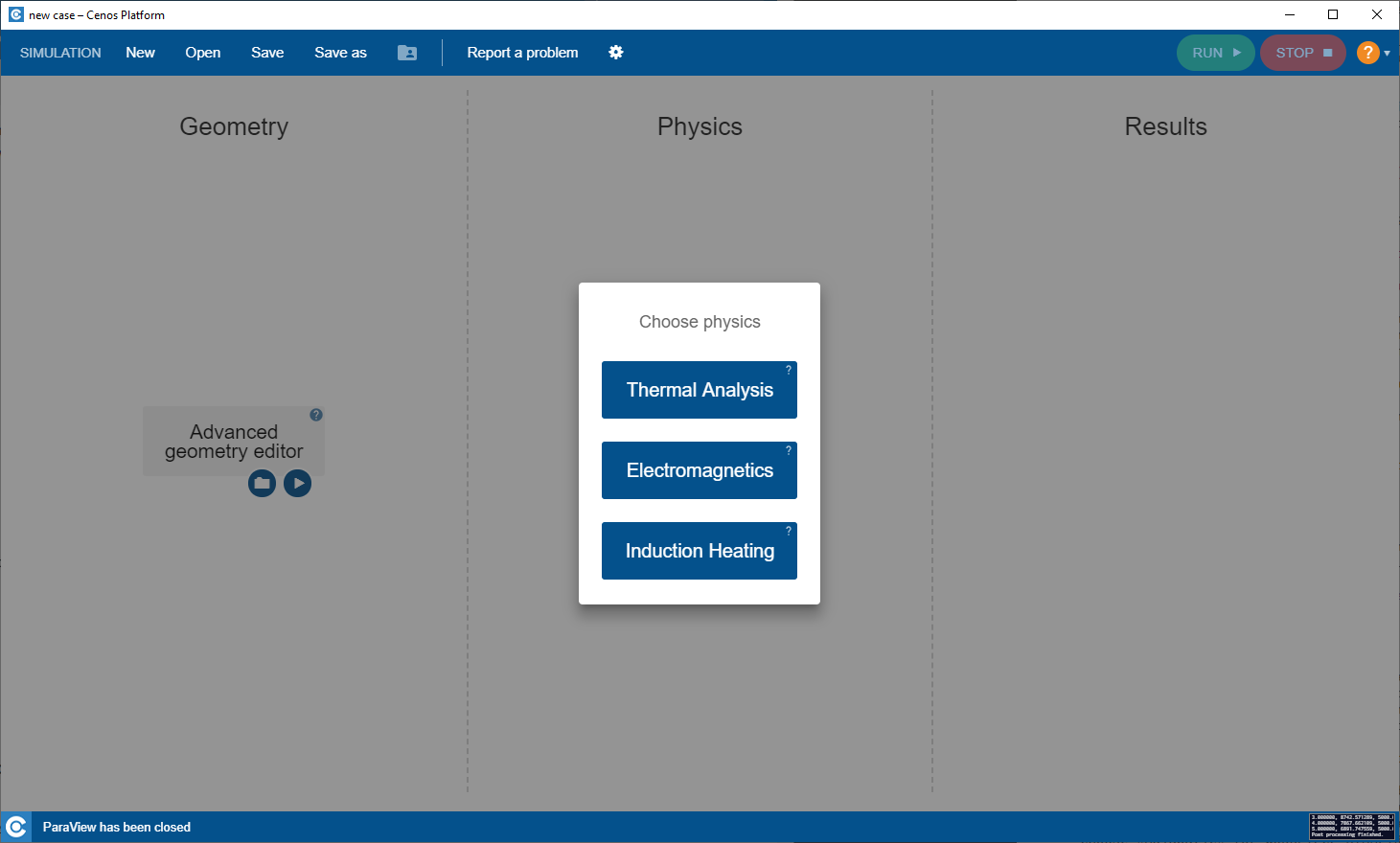

Click Induction Heating to select physics for simulation.

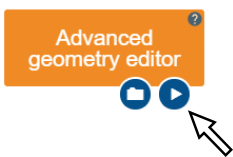

Click the Play icon to open Salome.

Salome window with already selected Shaper module will open.

2. Create geometry (Shaper) and prepare it for meshing

2.1 Create a new sketch

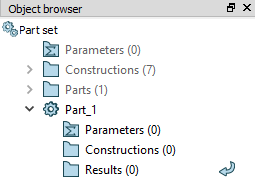

Create a new Part by clicking the New part ( ) tool. A new part will be added to Object browser.

) tool. A new part will be added to Object browser.

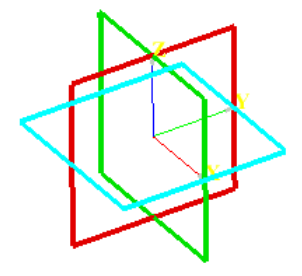

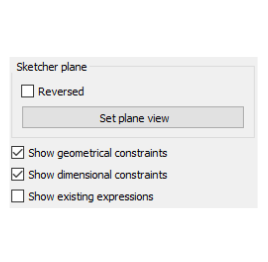

Now create a new Sketch by clicking the Sketch ( ) icon. Select the XY plane and click Set plane view.

) icon. Select the XY plane and click Set plane view.

You have now created an active sketch, in which you can start to build your geometry!

2.2 Create an air box

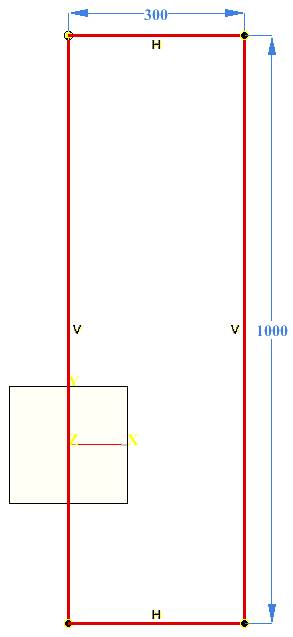

Select Rectangle ( ) tool and with a free hand draw a rectangle which left edge coincide with OY axis.

) tool and with a free hand draw a rectangle which left edge coincide with OY axis.

IMPORTANT: To simulate axial-symmetric cases, the symmetry axis must be Y axis.

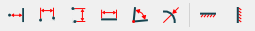

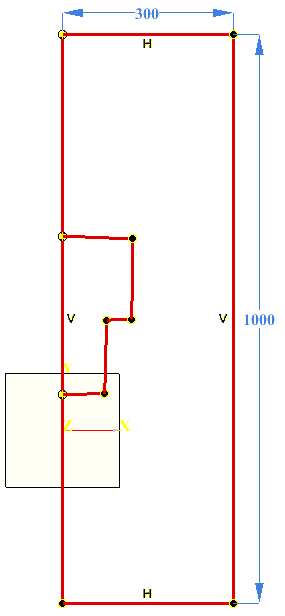

Select Length ( ) tool and define the size of the air box (300mm x 1000mm).

) tool and define the size of the air box (300mm x 1000mm).

2.3 Create workpiece

Select Line ( ) tool and with a free hand draw a Stepped Shaft outline.

) tool and with a free hand draw a Stepped Shaft outline.

Then by using Horizontal and Vertical ties and Length and Distance tools define the size and position of the outline based on the sketch presented in the beginning of this tutorial.

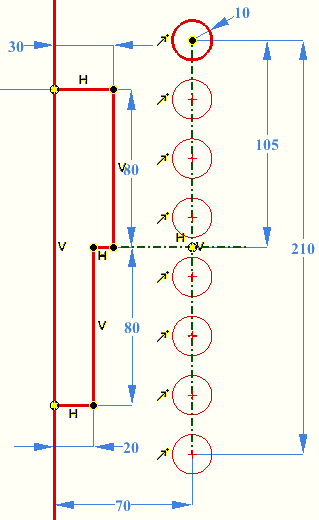

2.4 Create coil windings

First you need to create windings separately and then align them with the workpiece.

To create coil windings:

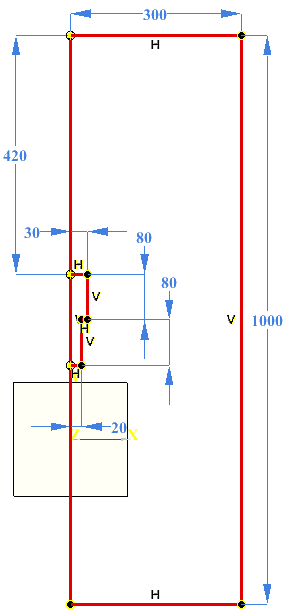

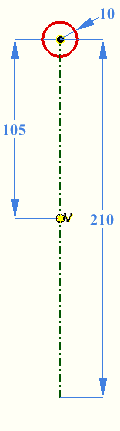

Select Circle (

) tool and with a free hand draw a circle. Using Radius (

) tool and with a free hand draw a circle. Using Radius ( ) tool define the size of the circle (10 mm radius).

) tool define the size of the circle (10 mm radius).Select Line (

) and draw an auxiliary line from the center of the circle. Using Vertical (

) and draw an auxiliary line from the center of the circle. Using Vertical ( ) and Length (

) and Length ( ) tools define the position (vertical) and size (210 mm) of the line.

) tools define the position (vertical) and size (210 mm) of the line.Select Point (

) tool and create a point in the middle of the line. By using Distance (

) tool and create a point in the middle of the line. By using Distance ( ) tool define the point distance from one end of the line (105 mm).

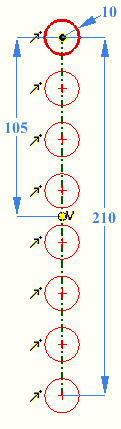

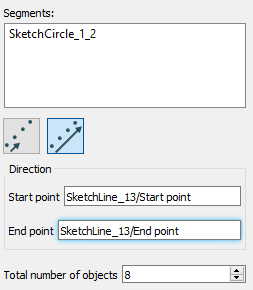

) tool define the point distance from one end of the line (105 mm).Select Linear copy (

) tool. Select circle as Segments,the circle centre point as Start point and the other end of the line as End point, and translate the circle along the line 8 times (Total number of objects).

) tool. Select circle as Segments,the circle centre point as Start point and the other end of the line as End point, and translate the circle along the line 8 times (Total number of objects).

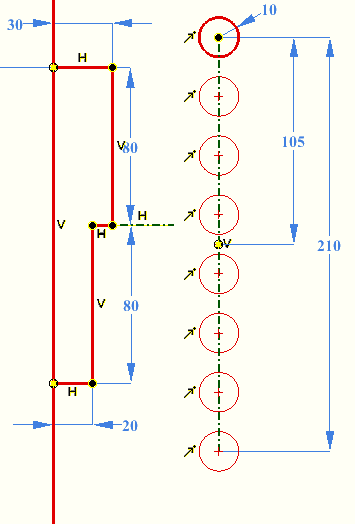

To align windings with the workpiece:

Using Line (

) tool draw a horizontal auxiliary line from the shaft step corner. Use the Horizontal (

) tool draw a horizontal auxiliary line from the shaft step corner. Use the Horizontal ( ) constraint to define the position of the line (horizontal).

) constraint to define the position of the line (horizontal).Select Coincident (

) tool to align the newly created auxiliary line with the center point of the winding centre line. Set the distance between air box outer edge and winding centre line (70 mm)

) tool to align the newly created auxiliary line with the center point of the winding centre line. Set the distance between air box outer edge and winding centre line (70 mm)

When sketch is finished, click Apply ( ) in Sketch window.

) in Sketch window.

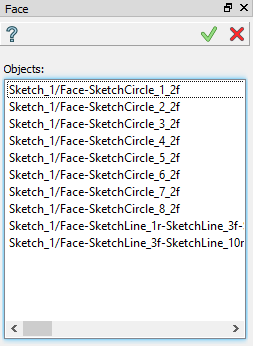

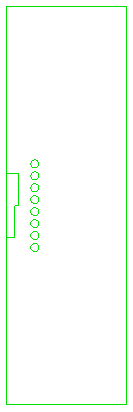

2.5 Create faces for your geometry

Select Face ( ) tool and create faces for each winding, workpiece and air.

) tool and create faces for each winding, workpiece and air.

IMPORTANT: You can select multiple geometry objects by holding the Shift button and clicking on the objects of interest.

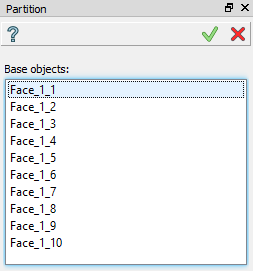

2.6 Create Partition and Groups

Click Partition ( ) tool, select previously created faces and join them in one partition.

) tool, select previously created faces and join them in one partition.

IMPORTANT: Partition and Groups are vital for simulation setup with CENOS, because mesh creation as well as physics and boundary condition definitions are based on groups created in this part.

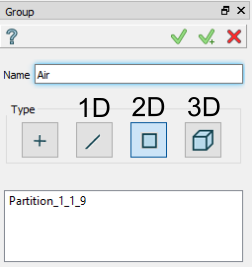

Select Group ( ) tool and choose the Shape Type. Select one or more shapes from the screen, name the group and click the Apply and continue (

) tool and choose the Shape Type. Select one or more shapes from the screen, name the group and click the Apply and continue ( ).

).

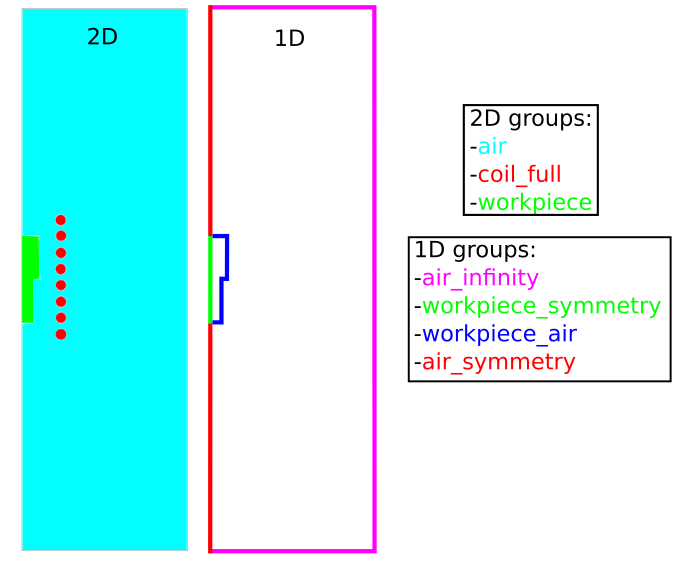

For this tutorial we will create eleven 2D groups for domains and four 1D groups for boundary conditions. When creating groups, select only those objects relevant for the specific group.

IMPORTANT: For the coil create one 2D group with all of the windings in it (coil_full), which will be used to ease the meshing of the coil, but also create separate 2D group for each winding (c1, c2...), because these will be used to define current flowing through each winding in the physics setup part.

A detailed breakdown of these groups is as follows:

2.7 Export to GEOM

Finally we need to export the geometry created in Shaper to GEOM module. Do this by clicking Export to GEOM ( ). This will export the Partition and Groups to GEOM module, which is needed to proceed with mesh creation.

). This will export the Partition and Groups to GEOM module, which is needed to proceed with mesh creation.

3. Create mesh and export it to CENOS

3.1 Switch to Mesh module and create Mesh

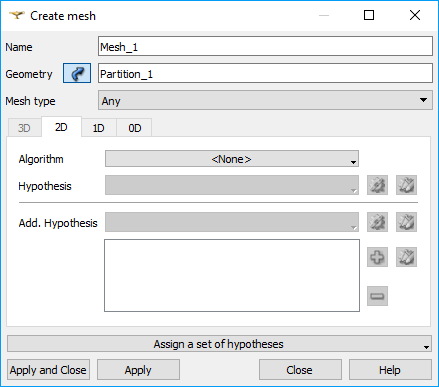

Switch to the Mesh module through Mesh icon or select it from the Salome module dropdown menu.

In Object Browser from Geometry dropdown menu select the previously created Partition_1_1 and click Create Mesh ( ).

).

From the Assign a set of hypothesis dropdown menu select 2D: Automatic Triangulation - leave the Max Length value default and click Apply and Close.

3.2 Create a sub-mesh for the workpiece

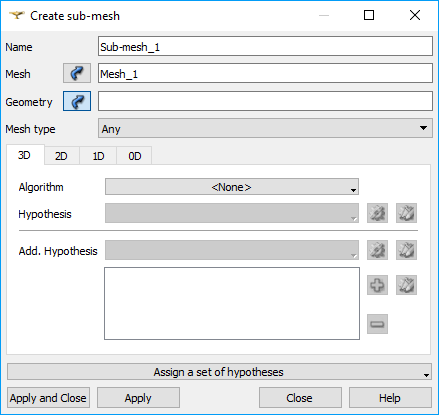

Right-click on Mesh_1 and click Create Sub-Mesh or select Create Sub-mesh ( ) from the toolbar.

) from the toolbar.

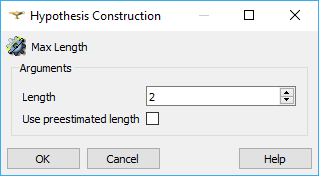

Choose workpiece group from the Partition_1_1 dropdown menu as Geometry. From the Assign a set of hypothesis dropdown menu choose 2D: Automatic Triangulation. In the Hypothesis Construction window enter 2 for Max Length.

Resolve the skin layer on the surface of the workpiece by creating Viscous Layers. Click the gear icon ( ) next to Add. Hypotheses and select Viscous Layers 2D.

) next to Add. Hypotheses and select Viscous Layers 2D.

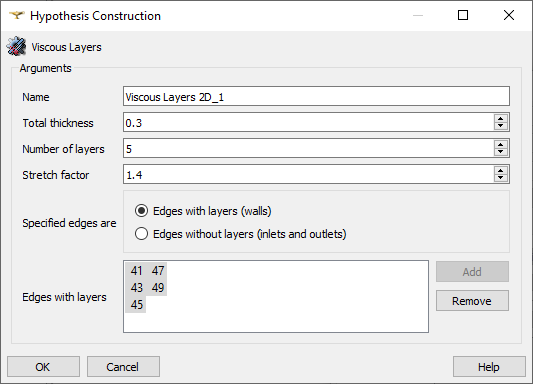

Select the group workpiece_air from the Partition_1_1 dropdown menu and click Add. Enter 0.3 for Total thickness, 5 for Number of layers, 1.4 for Stretch factor and check the Edges with layers (walls) box.

When all is set, click Apply and Close.

3.3 Create a sub-mesh for the coil

If we had only created groups for each winding separately, we would need to mesh each winding separately, which would be time consuming. For this reason, we created a group with all of the windings together.

Create a sub-mesh and select the coil_full group from the Partition_1_1 dropdown menu as Geometry. From the Assign a set of hypothesis dropdown menu choose 2D: Automatic Triangulation and enter 2 for Max Length.

Resolve the skin layer on the surface of the inductor by creating Viscous Layers. Click the gear icon ( ) next to Add. Hypotheses and select Viscous Layers 2D.

) next to Add. Hypotheses and select Viscous Layers 2D.

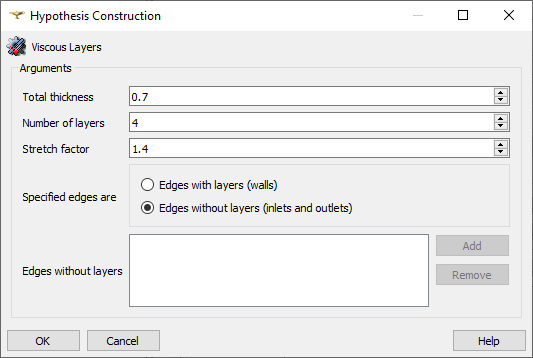

Enter 0.7 for Total thickness, 4 for Number of layers, 1.4 for Stretch factor and check the Edges without layers (walls) box.

3.4 Calculate and export mesh to CENOS

Right-click on Mesh_1 and click Compute. Evaluate the final mesh and export it to CENOS. To do that, select Mesh to CENOS from the dropdown menu under Tools → Plugins → Mesh to CENOS to export your mesh to CENOS.

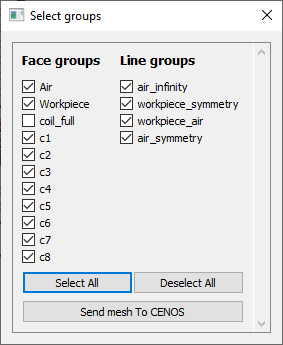

Before exporting mesh to CENOS, the Select groups window will open and you will be asked to select the groups you want to export along with the mesh.

Select all groups relevant for the physics setup, i.e. those who will be defined as domains or boundary conditions. We will select all groups except coil_full.

When selected, click Send mesh to CENOS.

4. Define physics and boundary conditions

4.1 Set units and enter physics setup

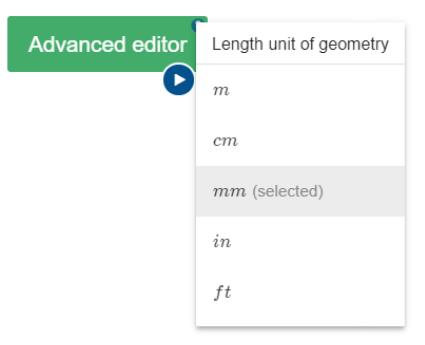

Wait until the mesh loads (see the spinner) and select the units by clicking on the gear icon next to the pre-processing block. In this tutorial we will select millimeters (mm).

Click the gear icon under Induction Heating block to enter the physics setup.

4.2 Simulation control

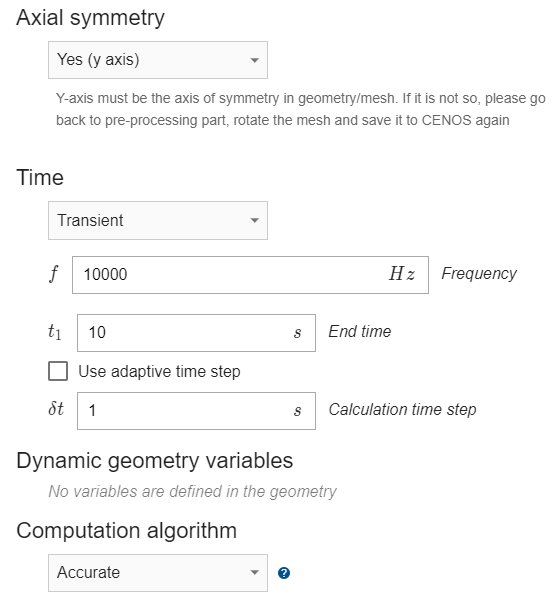

In SIMULATION CONTROL window define the simulation as axial symmetric and transient with 10 kHz frequency, 10 s End time and 1 s time step. For Computation algorithm choose Accurate.

4.3 Workpiece definition

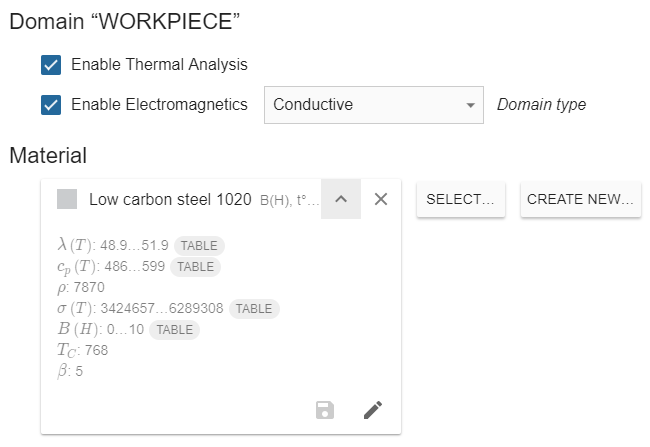

Switch to WORKPIECE in Domain bar. Leave Enable Thermal Analysis and Enable Electromagnetics boxes checked under the Domain “WORKPIECE”. Choose Conductive as the domain type. For Material click SELECT… and choose Low carbon steel 1020 B(H), depend.

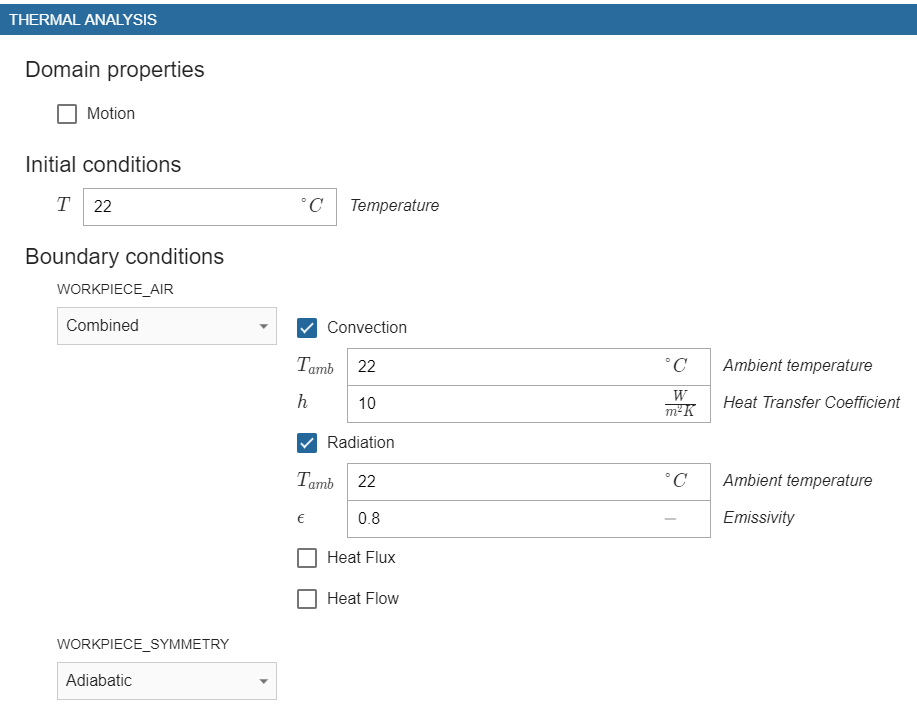

Under THERMAL ANALYSIS for boundary conditions choose Combined for WORKPIECE_AIR – check the Convection and Radiation boxes and enter 10 for Heat Transfer Coefficient and 0.8 for Emissivity. Choose Adiabatic for WORKPIECE_SYMMETRY.

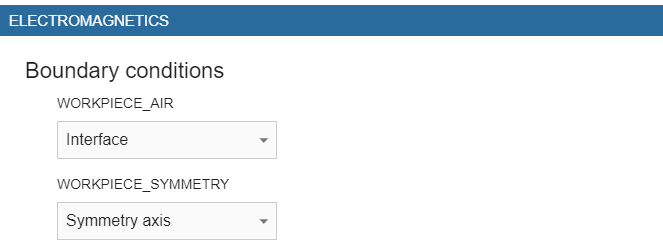

Under ELECTROMAGNETICS choose Interface for WORKPIECE_AIR and Symmetry axis for WORKPIECE_SYMMETRY.

4.4 Coil definition

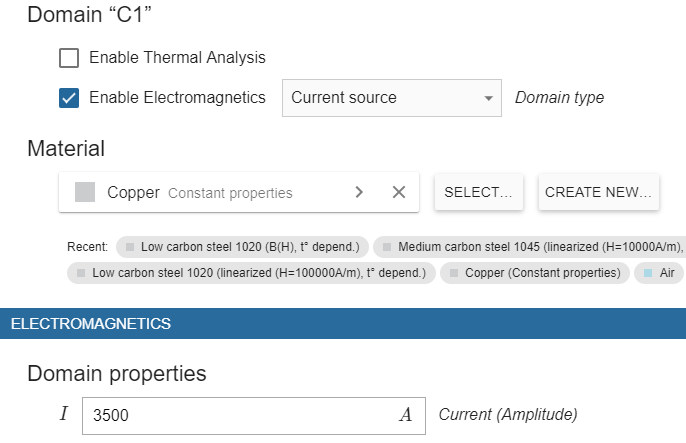

We created 8 different domains for each winding in order to define the current for each of them. To save time, it is possible to group these domains and define them all through one Setup window. To do that, select all winding domains and click GROUP.

Disable Thermal analysis and select Current source for Domain type. For Material choose Copper Constant properties and enter 3500 A for Current (Amplitude).

4.5 Air definition

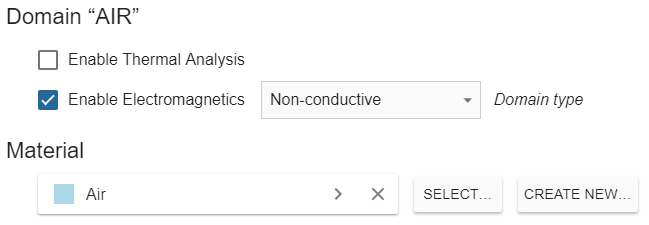

Switch to AIR in Domain bar. Disable Thermal analysis and select Non-conductive as Domain type. For Material choose Air.

Under ELECTROMAGNETICS choose Infinity for AIR_INFINITY, Symmetry axis for AIR_SYMMETRY and Interface for WORKPIECE_AIR.

When everything is set, click RUN.

5. Evaluate results

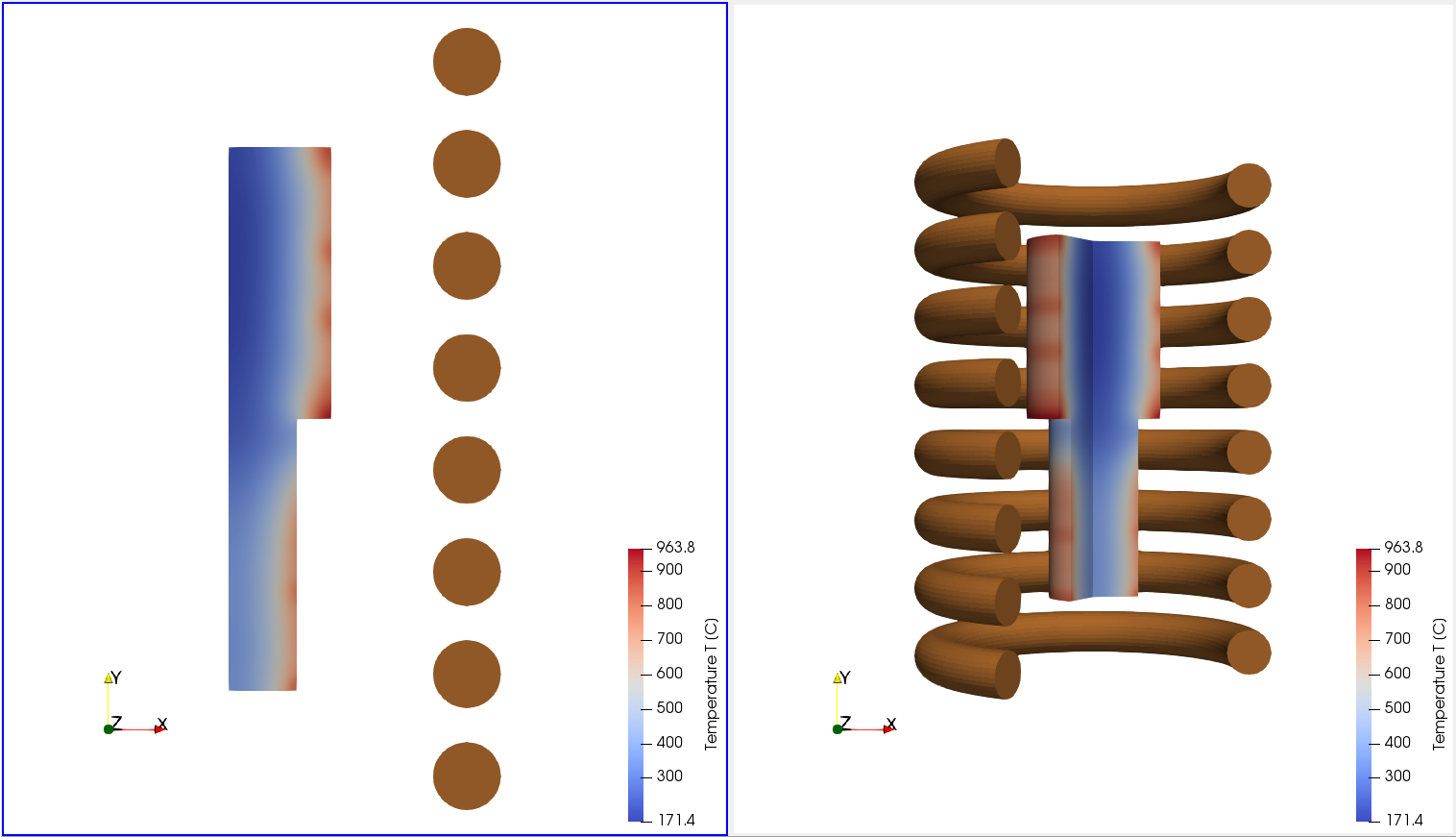

When CENOS finishes calculation, ParaView window with pre-set temperature result state will open automatically and you will be able to see the temperature field distribution in workpiece in the last time step as well as a 3D revolution of the results to give you better visual interpretation.

Results can be further manipulated by using ParaView filters - find out more in CENOS advanced post-processing article.

This concludes our Induction Heating Template tutorial. For any recommendations or questions contact our support.